How to Improve Fibre Optic Quality Control with the Optical Fibre Diameter Analyser

How to Improve Fibre Optic Quality Control with the Optical Fibre Diameter Analyser

Blog Article

Exactly How an Optical Fibre Diameter Analyser Enhances Quality Assurance in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser right into Fibre manufacturing procedures represents a considerable innovation in quality control approaches. By using real-time, specific dimensions of Fibre diameters, this modern technology addresses the vital requirement for consistency in production criteria.

Significance of Fibre Diameter Dimension

Accurate measurement of Fibre Diameter is vital in the field of optical Fibre innovation, as it straight affects the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre affects its light-carrying capability, depletion, and total transmission effectiveness. Accuracy in measuring Fibre Diameter ensures that the optical residential properties are preserved within specified tolerances, which is important for ideal signal stability.

Variations in Fibre Diameter can lead to boosted losses due to spreading and modal dispersion, influencing the quality of information transmission. In high-speed interaction systems, such inconsistencies can cause considerable degradation of signal top quality, bring about data mistakes and lowered performance. In addition, consistent Fibre Diameter is crucial for compatibility with ports and splicing modern technologies, which are integral parts of Fibre optic networks.

Quality assurance processes in Fibre manufacturing heavily depend on exact Diameter measurements to guarantee conformity with industry requirements. By implementing robust dimension techniques, manufacturers can improve product integrity, decrease waste, and enhance total system efficiency. Thus, the significance of Fibre Diameter dimension can not be overemphasized, as it acts as a cornerstone in the development of optical Fibre modern technology and its applications in contemporary interaction networks.

Just How the Analyser Works

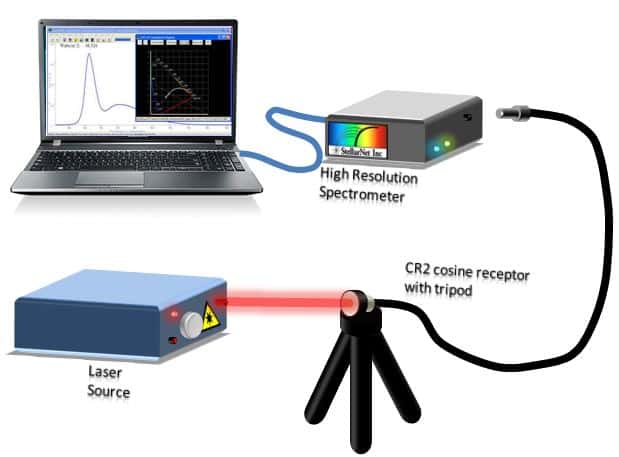

The effective dimension of Fibre Diameter counts on advanced analytical techniques that make certain accuracy and dependability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a combination of laser innovation and advanced image processing formulas to accurately assess the Diameter of fibres as they are generated

At first, a laser beam is guided at the relocating Fibre, producing a cross-sectional shadow. The analyser captures this shadow using high-resolution video cameras positioned purposefully along the manufacturing line. The captured images are after that processed in real-time to figure out the Fibre's Diameter with exceptional precision.

The system makes use of advanced algorithms that make up various aspects, including variants in light intensity and ecological problems, to improve measurement integrity. It can find minute adjustments in Diameter, such as changes that could occur throughout the manufacturing process.

Furthermore, the analyser is capable of dealing with multiple fibers at the same time, boosting throughput without endangering accuracy. By offering instant comments on the Diameter, the Optical Fibre Diameter Analyser plays a crucial function in maintaining rigid quality control criteria, making certain that the last product satisfies market specifications and consumer demands.

Advantages of Real-Time Tracking

While conventional approaches of checking Fibre Diameter typically involve taxing post-production checks, real-time tracking significantly boosts the efficiency and top quality of optical Fibre production. optical fibre diameter analyser. This proactive technique allows makers to identify variances in Fibre Diameter as they take place, instead of waiting up until manufacturing is total to analyze quality

By constantly measuring the Diameter throughout manufacturing, producers can make certain that the fibres satisfy rigorous specs, bring about reduced variability and boosted consistency. Real-time tracking additionally makes it possible for instant rehabilitative actions to be taken, decreasing waste and preventing faulty fibers from getting in the supply chain.

Additionally, this innovation promotes enhanced data collection and evaluation, giving insights into production patterns and possible locations for improvement. Such data-driven decision-making equips suppliers to maximize processes and maintain high requirements of quality dig this assurance.

Furthermore, real-time surveillance fosters a culture of continuous enhancement within the production atmosphere. Workers are a lot more engaged when they can see the impact of their operate in real-time, resulting in increased responsibility and a commitment to excellence. In general, the implementation of real-time monitoring systems in optical Fibre manufacturing converts to premium item top quality and boosted client satisfaction.

Effect On Manufacturing Effectiveness

Carrying out optical Fibre Diameter analysers significantly boosts manufacturing effectiveness by improving the manufacturing procedure. These gadgets help with continuous monitoring of Fibre Diameter, allowing makers to spot variances in real-time. By identifying variances immediately, assembly line can be readjusted quickly, decreasing downtime and lowering the probability of producing malfunctioning items.

Additionally, the assimilation of these analysers right into the production operations makes it possible for better source allowance. With accurate Diameter measurements, drivers can enhance product use, making sure that sources are not thrown away on flawed fibres. This precision additionally contributes to much less rework and junk, eventually decreasing production prices.

The automation offered by optical Fibre Diameter analysers minimizes dependence on hands-on examinations, which are commonly time-consuming and susceptible to human error. As an outcome, employees can concentrate on even more strategic tasks, boosting overall efficiency.

In addition, the data produced from these analysers can educate procedure improvements and assist her comment is here in far better decision-making. By evaluating patterns in Fibre Diameter variants, producers can carry out aggressive measures to enhance production methods and keep consistent quality. In summary, optical Fibre Diameter analysers play an essential role in increasing production effectiveness, bring about better output and enhanced success.

Situation Researches and Success Stories

Throughout numerous fields, case studies highlight the transformative impact of optical Fibre Diameter analysers on production processes. One prominent example is a best site leading telecommunications company that dealt with difficulties with inconsistent Fibre diameters, leading to increased rejection rates. By integrating an optical Fibre Diameter analyser, the firm achieved real-time monitoring of Fibre measurements, leading to a 30% reduction in problems and considerable cost savings.

In addition, a research study establishment focusing on innovative materials used optical Fibre Diameter analysers to improve their experimental procedures. The analyser's capacity to offer thorough insights right into Fibre consistency made it possible for the development of ingenious products with improved performance features.

These success stories highlight the essential function of optical Fibre Diameter analysers in enhancing quality assurance, boosting production effectiveness, and driving technology across diverse markets.

Verdict

In conclusion, the Optical Fibre Diameter Analyser plays a crucial role in boosting top quality control within Fibre manufacturing. As demonstrated with various case research studies, the analyser verifies vital for accomplishing exceptional product quality in Fibre production.

The execution of optical Fibre Diameter analysers permitted for strict top quality control, guaranteeing that the generated fibres satisfied exacting sector requirements.In verdict, the Optical Fibre Diameter Analyser plays an essential role in improving top quality control within Fibre production.

Report this page